In industrial asset management, ensuring the integrity and performance of coatings is paramount. These protective layers serve as the first line of defense against a variety of environmental and operational threats that can compromise the longevity and functionality of critical infrastructure. Toronto Industrial stands at the forefront of this essential service, offering unparalleled expertise in coating inspection across diverse industries. By prioritizing asset integrity maintenance through rigorous inspection practices, we safeguard our clients’ investments and contribute to the sustainability of valuable industrial assets.

On this page

Understanding Coating Inspection

Coating inspection is a comprehensive process designed to evaluate the effectiveness and longevity of protective coatings applied to industrial equipment, structures, and facilities. This meticulous examination plays a crucial role in preventing premature failures, extending asset life, and ensuring safety and regulatory compliance. Key aspects of a coating inspection include visual assessment, thickness measurement, adhesion testing, and monitoring of environmental conditions during application and curing phases. Through these inspections, potential issues such as corrosion, blistering, and inadequate coverage can be identified and addressed before resulting in significant damage or operational disruptions.

Factors Influencing Inspection Cost

The cost of conducting a coating inspection is influenced by several critical factors. The level of certification of the inspectors, as delineated by the AMPP (Association for Materials Protection and Performance), significantly impacts the inspection’s depth and reliability. Inspectors are classified into Levels 1, 2, and 3, with each level denoting a higher degree of expertise and capability. Furthermore, the complexity of the project and the scope of the inspection required to thoroughly assess the coating’s condition can vary dramatically, affecting the overall cost. Additionally, logistical challenges and the specific location of the project can also play a significant role in determining the inspection expense.

Market Challenges:

In recent times, the coating industry has observed a concerning trend: the rise of third-party coating inspectors and freelancers offering inspection services at significantly reduced rates. This development, while financially attractive at first glance, introduces a myriad of challenges for the market. Vijesh Vijayan, a notable voice in the industry, has articulated the ramifications of this trend: “The presence of low-cost coating inspectors with NACE/FROSIO Level 2, 3 certification poses a significant threat to the market. Offering services at incredibly low rates often compels clients to prioritize cost over quality. This not only devalues our expertise but also undermines the trust and confidence clients place in us”.

This shift towards cost-centric choices can endanger the structural integrity and safety of industrial assets by sidelining the quality and depth of the inspection process. It places experienced professionals in a tight spot, struggling to secure engagements or to maintain a competitive pricing structure without compromising on quality.

Moreover, Vijayan’s insights shed light on the broader implications of such practices: compromising work quality and devaluing proper certification. Certified inspectors, especially those with NACE or FROSIO Level 2 and 3 credentials, have completed extensive training and possess the field experience necessary to identify and address potential issues effectively. Their fees reflect the depth of their expertise and the critical role they play in ensuring project quality and asset longevity.

Emphasizing Quality and Expertise:

In this challenging landscape, it’s imperative for clients and service providers alike to prioritize the long-term benefits of quality inspections conducted by certified professionals. Doing so not only safeguards the structural integrity of assets but also promotes a market environment that values expertise, ethical practices, and the maintenance of high industry standards.

Acknowledging these market dynamics allows us to navigate these challenges with a greater emphasis on quality, expertise, and the ethical provision of services. It underscores the importance of making informed decisions that support the sustainability and safety of industrial assets over mere cost-saving measures.

Toronto Industrial Painting’s Inspection Services

Toronto Industrial offers a comprehensive array of coating inspection services tailored to meet the needs of different industries. With a team of AMPP-certified inspectors, they possess the proficiency to identify a wide range of issues, from corrosion under insulation to damaged paint systems. “Our inspection services are not limited to post-application assessments but also encompass pre-application consultations to ensure the selection of appropriate coating systems and application methodologies. This proactive approach enables the identification and rectification of potential issues before they evolve into costly problems.”

Cost Structure for Coating Inspection

While the specific cost of a coating inspection can vary based on previously mentioned factors, we are committed to providing transparent and equitable pricing. Our cost structure is thoughtfully designed to reflect the inspection’s complexity, the certification level of the inspectors involved, and the specific project requirements.

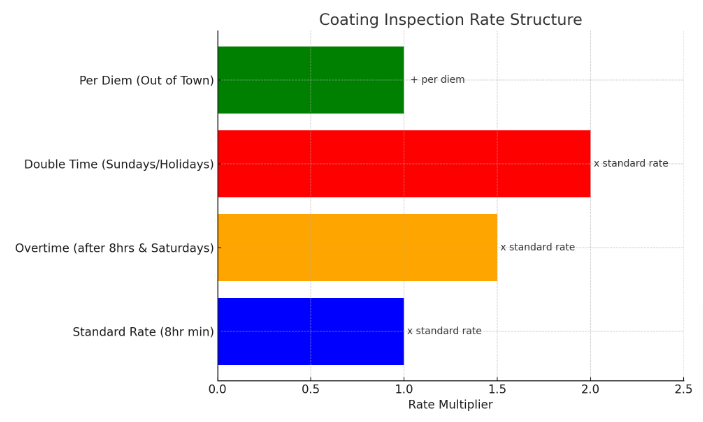

At Toronto Industrial, we charge an hourly rate with an 8-hour minimum to ensure that our clients receive comprehensive and thorough inspection services. This approach facilitates the deployment of our certified and experienced inspectors to projects of any scale, guaranteeing meticulous attention to detail and the high-quality service our clients have come to expect. For any work extending beyond the standard 8 hours, including inspections on Saturdays, overtime rates apply, fairly compensating our professionals for their extended availability. Furthermore, work on Sundays or holidays is billed at double time, reflecting our team’s extra commitment to meet client timelines and project demands outside regular working hours.

For out-of-town projects, we also charge a daily per diem rate to cover the travel and accommodation expenses incurred by our inspectors. This ensures that distance and location do not hinder our ability to deliver top-tier inspection services to clients, regardless of their location.

Here’s a simple graph illustrating the rate structure for coating inspections, including the standard rate with an 8-hour minimum, overtime and double time rates, as well as the daily per diem rate for out-of-town projects. Each category is represented with a multiplier to the standard rate, providing a clear visual of the pricing model.

Investing in a professional inspection through Toronto Industrial is a decision that underscores the importance of quality, reliability, and long-term asset protection. It’s not merely an expenditure; rather, it’s a strategic investment that can significantly mitigate the risk of costly repairs or replacements in the future. By preempting potential issues through expert inspection, clients can enjoy peace of mind, knowing that their assets are maintained to the highest standards.

Customized Inspection Plans

Recognizing that each client has unique needs and budget constraints, Toronto Industrial offers customized inspection plans. These tailored solutions are devised in close collaboration with clients, ensuring that the inspection services provided align perfectly with their specific requirements and financial considerations. This client-centric approach highlights our commitment to delivering value and excellence in every project we undertake.

How Much Do Coating Inspections Cost?

A lot less than it costs to neglect them. This might seem like a simple assertion, but it captures the essence of the value proposition offered by comprehensive coating inspections. When considering the financial implications of coating inspections, it’s crucial to juxtapose the upfront costs against the potential expenses associated with premature coating failures, corrosion, or structural damage. These latter scenarios often lead to costly repairs, significant downtime, and, in severe cases, complete asset replacement.

While the exact cost of a coating inspection by Toronto Industrial or any reputable service provider will vary based on factors such as the project’s complexity, the scope of inspection required, and the level of expertise of the inspectors, investing in these services is fundamentally about securing the longevity and reliability of your assets. For example, a standard inspection for a mid-sized industrial facility could range from a few hundred to several thousand dollars, a figure that is significantly dwarfed by the potential costs of addressing extensive corrosion or coating system failures, which can easily run into the tens or even hundreds of thousands.

Moreover, the cost-effectiveness of coating inspections becomes even more apparent when considering the added value they provide in extending the lifespan of an asset, improving performance, and ensuring compliance with industry standards and regulations. By identifying and addressing potential issues early on, businesses can avoid the steep costs associated with major repairs or replacements and minimize operational disruptions.

Ultimately, the question isn’t so much about how much a coating inspection costs, but rather, how much you can save by proactively maintaining the integrity of your coatings. With the tailored and expert services offered by providers like Toronto Industrial Painting, the investment in coating inspection is a prudent step towards safeguarding your assets, optimizing operational efficiency, and ensuring the safety of your infrastructure.

Conclusion

Selecting a professional, AMPP level 3 certified surface inspection company is a critical decision that can significantly impact the longevity and performance of industrial assets. Toronto Industrial Painting, with its team of skilled AMPP-certified inspectors and comprehensive suite of inspection services, stands as a trusted partner in maintaining asset integrity. Prospective clients are encouraged to reach out for a consultation to discuss their inspection needs and receive a customized cost estimate. In entrusting your coating inspection needs to Toronto Industrial Painting, you ensure not just the protection of your assets but also the optimization of your investment in maintenance and asset management practices.

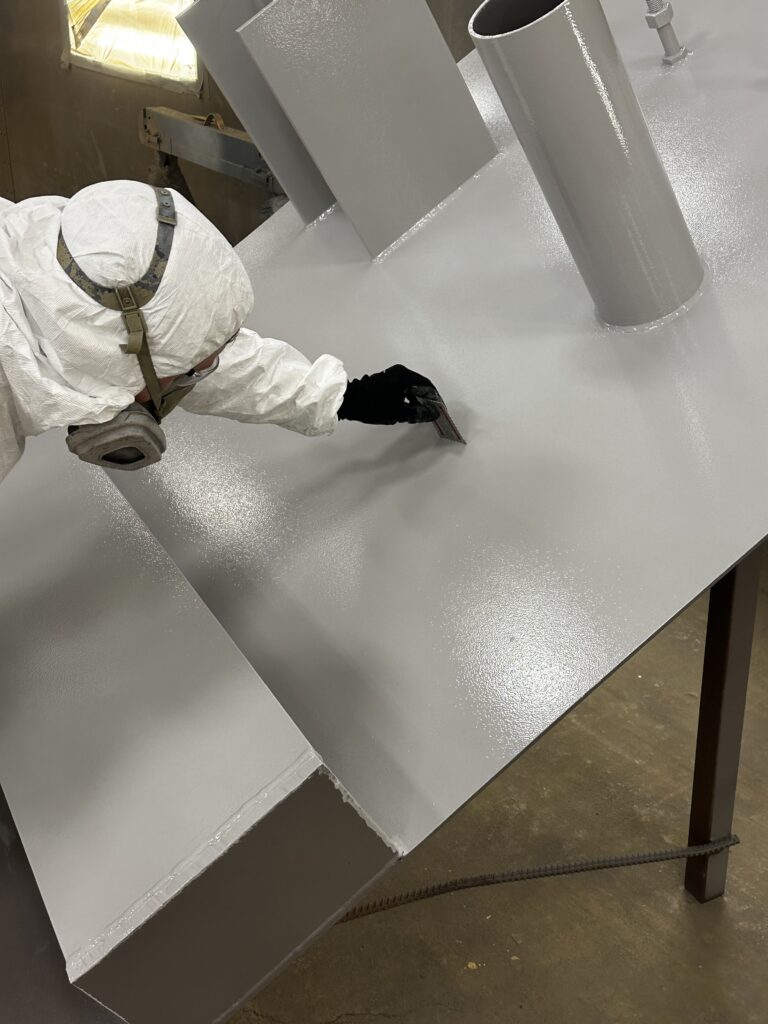

We’re thrilled to share a glimpse into one of our recent ventures at Toronto Industrial Coating Consultants, where our commitment to excellence and our expertise in the industrial coatings industry truly shines. 🌟

As a NACE-certified coating inspector with over 30 years of experience, we hold ourselves to the highest standards of service and quality. Our recent project took us on an exciting journey, dedicating several days to certifying painters for a US Army Corps of Engineers specified project. This task was not only a testament to our team’s skill and dedication but also a privilege, as it involved a critical role in ensuring the highest quality of workmanship for a project of national significance.

🎥 Check out our video to see our team in action during the coating inspection and certification process. It’s moments like these that remind us of the impact our work has, not just locally in Southern Ontario, but on a much larger scale.

This project underscores our commitment to delivering outstanding service and the importance of having a skilled, NACE-certified team ready to meet the challenges of any project, big or small. We’re proud to contribute our expertise to such a vital and prestigious project, ensuring safety, durability, and the highest standards of industrial coatings.

To our team, partners, and clients, thank you for your trust and support in making projects like these a success. We look forward to continuing to serve the industrial coatings needs of Southern Ontario and beyond with the same level of excellence and dedication.

Stay tuned for more updates and insights into our work. Your trust drives us to achieve greater heights.

Feel free to reach out for more information about our services or to discuss your next project.

In the intricate world of industrial painting, the smallest oversight can have cascading effects on the quality and longevity of the final product. One of the often-overlooked yet crucial elements in this process is the illumination of the work area. Ensuring the right lighting not only aids in achieving top-notch workmanship but also ensures that inspections meet project specifications and requirements. The question arises, how can the delicate balance of proper illumination be maintained without compromising safety?

The Lighting Challenge

Illumination in the workplace presents a unique set of challenges. On the one hand, proper visibility is vital for ensuring work is up to standard. On the other, excessive or impractical lighting can pose safety risks. The task becomes further complicated when the nature of the job necessitates varied lighting conditions, as is the case with industrial painting.

The Role of Proper Illumination in Inspections

For an inspection to be accurate and efficient, the work area must be adequately lit. This ensures that the coating inspector can clearly see any discrepancies or deviations from the required standards. When the illumination is insufficient, not only does it jeopardize the quality of the inspection, but it also undermines the value of the project specifications and requirements.

However, illumination isn’t just about quantity; it’s also about quality. An overly bright light source can be obstructive, and in the delicate dance of industrial painting, this can cause more harm than good. NACE certified coating Inspectors and workers alike need a light source that aids their task without becoming a hindrance.

Guidance from the Industry: SSPC-Guide No 12

Thankfully, the coatings industry isn’t in the dark about this crucial aspect. The SSPC-Guide No 12, “Guide for Illumination of Industrial Painting Projects”, freshly re-released in 2023, is a beacon of guidance in this matter. While it serves as a guide specific to the coatings industry, its contents are invaluable to both specifiers and contractors.

This guide sheds light on the types of lighting necessary, factoring in various hazards and operational conditions. It gives explicit illumination levels required for specific tasks—ranging from surface preparation to coating application, and crucially, inspection. The guidelines emphasize not just on generic lighting but delve deep into recommendations for task lighting, inspection light, and supplemental lighting. It addresses challenges like explosion-safe lighting and offers insights into technical aspects like foot candles and lux.

Lighting, while seemingly straightforward, plays a pivotal role in ensuring that industrial painting projects meet the stringent standards set by project specifications and requirements. With resources like the SSPC-Guide No 12, contractors and inspectors can navigate the often murky waters of work area illumination with confidence.

In 2021, the world was taken aback by a grave revelation – whistleblowers across North America came forward to raise alarms about potential safety concerns involving major pipelines. This incident, although not recent, serves as a timely cautionary tale of the paramount importance of coating inspection in safeguarding the integrity of our critical infrastructures.

A Look Back at the 2021 Incident

The whistleblowers unveiled potential pitfalls in the quality of materials and workmanship within some of the continent’s most significant pipeline projects. These lapses could have resulted in catastrophic environmental and economic repercussions. At the heart of their concerns was a recurring theme: the silent but relentless enemy known as corrosion.

Corrosion compromises the longevity and safety of essential infrastructures, ranging from vast pipelines to crucial water storage tanks and bridges. The pivotal role of a coating inspector is to ensure that these structures remain shielded against the destructive power of corrosion with robust, high-quality coatings.

Why NACE Certification Matters

So, what sets a NACE-certified inspector apart in this crucial responsibility? The National Association of Corrosion Engineers (NACE) is globally renowned for its rigorous certification programs that signify an inspector’s comprehensive knowledge and unwavering commitment to the highest industry standards.

Holding a NACE Level 3 certification, as the team at Toronto Industrial Painting does, indicates an elite level of expertise. It’s not just about understanding corrosion; it’s about mastering both the theoretical and hands-on elements of corrosion control, coating inspection, and proficient project management.

Toronto Industrial Painting: Leading the Way in Surface Inspection

With its rich legacy, Toronto Industrial Painting has established itself as Ontario’s pinnacle in surface inspection. The services we offer encompass:

- Consulting: Our seasoned experts guide you, ensuring the optimal coating solution tailored to your project’s unique demands.

- Quality Assurance & Control: With eagle-eyed precision, we oversee every facet of your project, confirming that all procedures align with the zenith of industry standards.

- Failure Analysis: Should any aspect falter, our adept team delves deep, pinpointing the root cause and charting a course to avert future reoccurrences.

Our specialization in high-performance epoxies and urethane for structures, such as bridges and water tanks, ensures every project we undertake is meticulously managed for long-lasting safety and performance.

A Reminder of Our Responsibility

The 2021 whistleblower incident, though a couple of years behind us, is a potent reminder of the critical role of coating inspectors in maintaining the safety and durability of our infrastructure. In an era where structural integrity is non-negotiable, the onus is on us to prioritize excellence in inspection and coating application.

For a project that stands the test of time and elements, choose the unparalleled expertise of Toronto Industrial Painting. We’re not just NACE-certified; we’re your partners in ensuring excellence. Reach out to our dedicated team today and witness the difference meticulous inspection can make..

The realm of industrial coating is vast and continually evolving, with new standards and technologies being introduced frequently. Amidst this dynamic landscape, it’s imperative for professionals to stay updated and certified to guarantee the utmost quality in their projects. Toronto Industrial, a leading name in Ontario’s coating inspection industry, recognizes the significance of these certifications. Let’s delve into a comprehensive overview of the types of inspector certifications available and the importance of staying abreast with industry changes.

Distinguishing Between Different Certifications

SSPC Certifications

The Society for Protective Coatings (SSPC) has crafted several certifications catering to various industry needs:

- Concrete Coatings Inspector (CCI): Targeted towards professionals inspecting flooring or coatings on concrete. It emphasizes ensuring proper concrete preparation and accurate coating system installation.

- Bridge Coatings Inspection (BCI): Tailored for those inspecting coating applications on bridges and highways. This certification delves into the different elements of a bridge, making inspectors adept at recording intricate details during their assessments.

- Protective Coating Inspector Program: A holistic program that covers all industries where protective coatings are installed on steel. Although the primary focus is on steel as a substrate, the training is comprehensive, catering to various sectors.

NACE Certifications

The National Association of Corrosion Engineers (NACE) offers a program that is more general, spanning two weeks and dealing with various aspects of coating and lining installation. While there’s a resemblance between SSPC’s Protective Coating Inspector program and NACE’s offering, notable differences lie in the duration and depth of the programs.

Protective Coding Specialist (PCs) Certification

Both SSPC and NACE offer PCs certification, but it’s designed more for coding specifiers rather than inspectors. This certification is more about designing a coding project than inspecting one. Those certified under PCs are adept at tasks like lifecycle cost of coatings, assessing the condition of coatings, and preparing specifications.

Reciprocity and Keeping Up With Certifications

Interestingly, there’s no reciprocity between SSPC and NACE certifications. Therefore, one cannot substitute the credentials of one organization for the other. Also, like most professional certifications, maintaining them is crucial. Both SSPC and NACE certifications necessitate recertification every few years, emphasizing the importance of staying updated in the industry.

The Vitality of Staying Updated

With industry standards poised for revisions every five years and the plethora of standards from various bodies like ASTM, staying updated can indeed be a daunting task. However, it’s pivotal to be well-versed with the current standards, especially as they might feature prominently in specifications. Whether you’re inspecting based on those specifications or writing them, being unaware of the latest standards can lead to significant lapses in quality and compliance.

A Unified Future with AMPP

It’s noteworthy that NACE International and SSPC have now merged to form the Association for Materials Protection and Performance (AMPP). This unification aims to provide a consolidated voice for the corrosion control and protective coatings sectors. This new association, with its two governance structures, will undoubtedly bring forth more streamlined certifications and standards in the future.

Conclusion

While certifications are essential indicators of a professional’s expertise, the real essence lies in the continual learning and application of that knowledge. Toronto Industrial, with its commitment to quality and adherence to the highest standards, underscores the importance of having certified professionals on board and staying updated with industry advancements. As the coating industry keeps evolving, so does our commitment to excellence and upholding the highest standards.

Toronto Industrial stands as a beacon of excellence in Ontario for NACE Certified Coating Inspection services across Levels 1, 2, and 3. Our mission is not just about completing projects; it’s about preventing environmental and structural disasters that could compromise the integrity of your assets. Through rigorous inspections, best-practice recommendations, and quality assurance, we provide enduring solutions that keep your facilities safe and extend their lifespan.

Our Role and Qualifications

NACE Certified (Level 1/2/3) Coating Inspectors

Toronto Industrial is proud to offer a team of coating inspectors who are certified across NACE Levels 1, 2, and 3. These professionals spearhead our Inspection, Measurement, and Monitoring (IMM) initiatives, ensuring every project adheres to its specified drawings, conditions, and quality management plans.

Key Responsibilities

Thorough Review of Project Elements

Our team goes beyond merely reviewing construction drawings and specifications. We scrutinize every detail to guarantee alignment with the overarching project goals, while also considering environmental impacts and long-term effects.

Tailored Safety Programs

Safety is a core focus for us, and our approach extends past the usual Toolbox Talks and job safety analyses. We develop custom safety training modules tailored to the unique risks associated with each project.

Daily Accountability Through Reporting

We are committed to full transparency, providing daily reports that shed light on the day’s activities, progress, and issues. This practice empowers all stakeholders to make timely, informed decisions.

Comprehensive Quality Assurance

Quality assurance at Toronto Industrial is far more than a checklist; it’s a pledge to ensure the durability and longevity of your assets. This entails meticulous verification processes, from substrate cleanliness and coating batch numbers to application techniques and much more. Learn more from https://youtu.be/gxANBtRJE5g?si=u2bWeRxz_b2LADDl

Environmental Stewardship

Alongside project safety, we prioritize broader environmental concerns. This is vital for infrastructure projects like bridges and water tanks, which could have significant environmental impacts if not managed appropriately.

Experience and Skills

Versatile Expertise

Our team is well-versed in a wide variety of industrial and pipeline construction projects, possessing the skills needed to navigate the unique challenges of each.

Technological Savvy

We employ state-of-the-art software, including the MS Office Suite and other web-based applications, to ensure efficient project management and clear communications.

Swift Adaptability

Our team’s ability to adapt and find rapid solutions is invaluable in the fast-paced, deadline-driven work environments we often find ourselves in.

Education and Professional Certification

Every inspector at Toronto Industrial is NACE Certified, meeting and often exceeding industry standards. This guarantees a high level of competence and reliability.

From small facilities to expansive industrial complexes, Toronto Industrial offers unparalleled expertise in the specialized field of coating inspection and corrosion prevention. For those considering a project that traditionally requires other types of certifications, it’s worth noting that our NACE Level 3 qualifications could provide a superior level of expertise. Contact us today for a free consultation and see how our services can best meet your needs.

Toronto Industrial, as Ontario’s leading surface inspection company, specializes in all aspects of coating inspection services. From consulting and quality assurance to quality control and failure analysis, our NACE-certified level 3 inspectors are well-equipped to handle projects involving corrosion protection for infrastructures such as bridges, water tanks, and other industrial assets. However, in some instances, the role of an MPI (Master Painters Institute) Certified Architectural Coatings Inspector becomes critical. While NACE certification is generally considered a higher qualification, MPI certification is sometimes specifically required, depending on project needs and architectural stipulations. In such cases, a thorough understanding of what an MPI Certified Architectural Coatings Inspector is and what they do is crucial.

What is an MPI Certified Architectural Coatings Inspector?

An MPI Certified Architectural Coatings Inspector is a professional trained and certified by the Master Painters Institute to inspect, evaluate, and ensure the quality of paint and coatings used in architectural projects. This certification focuses particularly on coatings designed for buildings and other structures, taking into account both aesthetic and protective elements.

Responsibilities and Duties

Pre-Project Consulting

Before a project begins, an MPI Certified Architectural Coatings Inspector helps in consulting and planning to choose the appropriate materials and coatings. They evaluate the environmental conditions, substrate type, and other factors to recommend the most suitable coatings for optimum performance.

Quality Assurance

During the application phase, these inspectors are responsible for ensuring that the coatings meet the specifications set forth in the project documentation. They check the surface preparation, application methods, and curing conditions, verifying that all steps align with MPI standards for architectural coatings.

Quality Control

Ongoing checks during the application process are part of the inspector’s role. These involve visual inspections, adhesion tests, and dry film thickness measurements. Any deviations from the plan are immediately reported, and corrective measures are initiated.

Failure Analysis

In the event of coating failure, an MPI Certified Architectural Coatings Inspector will conduct a comprehensive analysis to determine the cause. They will make recommendations for remediation and future prevention.

The Synergy with NACE Certification

NACE (National Association of Corrosion Engineers) certification is more extensive in scope, covering various types of coatings including high-performance epoxies and urethanes designed to protect against corrosion in harsh industrial settings. However, an MPI Certified Architectural Coatings Inspector brings specialized expertise in architectural coatings, which could be necessary for projects involving aesthetic considerations alongside protective requirements.

Related: How do NACE and SSPC differ from each other?

When Does a NACE Level 3 Inspector Step In?

While NACE Level 3 certification is generally considered higher, there are instances where the specific expertise of an MPI Certified Architectural Coatings Inspector is required. If such an inspector is not available, a NACE Level 3 inspector can fill in but would usually need to have their qualifications approved by the project architect. Toronto Industrial, with its NACE-certified inspectors, has the experience and credentials to handle these roles effectively, given prior approval.

Whether you require a NACE level 3 inspector or an MPI Certified Architectural Coatings Inspector, the key is to have a qualified professional who can ensure the longevity and effectiveness of your coatings. These inspections are not just about meeting project specifications; they are about protecting your investment and ensuring the safety and aesthetic value of the structures for years to come.

For more information or a free consultation on your specific coating inspection needs, contact Toronto Industrial today at 416.444.5092.

Climate plays a crucial role in the successful application of industrial coatings. Numerous instances of coating failure have been linked to coatings applied when climatic conditions weren’t within the specified range. At Toronto Industrial Painting, an AMPP Level 3 certified surface inspection company, we recognize the importance of accurately measuring Relative Humidity and Dew Point temperatures in the field to prevent such failures.

Understanding Relative Humidity and Dew Point

Relative Humidity (RH) is the measure of how much moisture is in the air compared to the maximum amount of moisture the air could hold, given in percentage terms. Dew Point temperature is the temperature at which the air becomes fully saturated or reaches 100% RH. As a general rule, most project specifications require an RH below 85% and a minimum 5°F difference between the surface temperature and the Dew Point.

However, accurate measurements become increasingly important when the Humidity is near 85% (or the specified requirement) and the Dew Point/surface temperature spread is about 5°F.

Related: Understanding the Difference Between Quality Assurance and Quality Control

Measuring RH and Dew Point: Methods and Accuracy

There are two fundamental methods of measuring RH and Dew Point temperatures in the field, as outlined in ASTM E 337, Standard Method for Measuring Humidity with a Psychrometer. The traditional method employs a sling psychrometer, while modern practices favor electronic meters.

Sling psychrometers, used extensively by meteorologists, are generally considered to offer the most accurate method of determining RH and Dew Point. However, even the best psychrometers can expect an error range of 5% to 7%, and those typically used on coating projects may see even greater errors.

These devices measure two parameters – Dry Bulb (DBT or ambient temperature) and Wet Bulb (WBT) temperatures. WBT measures the temperature that results from evaporation, and is directly related to RH. The difference between the wet bulb and dry bulb temperature provides a measure of atmospheric humidity.

Enhancing Accuracy with Electronic Meters and Proper Procedure

Despite the traditional usage of sling psychrometers, we strongly recommend using electronic meters for optimal accuracy. If a sling psychrometer is used, certain steps should be followed to minimize potential errors:

- Ensure the thermometers are reading correctly by inspecting and calibrating them.

- Store the thermometers properly between uses to prevent heat-induced errors.

- Check the condition of the wick – it should be clean, white, and flexible. When possible, use distilled water and replace the wick if it becomes discolored or hard.

- When taking readings, follow a specific procedure, such as facing the wind if present and rotating the sling psychrometer at about 2 revolutions per second for about 90 seconds.

- Check readings in the area to be painted and compare dry bulb readings before and after the process to ensure consistency.

At Toronto Industrial Painting, our certified coating inspection professionals are equipped with the necessary knowledge and tools to conduct these critical measurements. Our commitment to quality and attention to detail help prevent expensive issues related to coating failures for our clients. Learn more about the three levels of NACE certification.

Are you looking for a pipeline inspector in Toronto? If you require expert advice or services in relation to industrial painting inspections, don’t hesitate to reach out to Toronto Industrial Painting. Quality isn’t just a part of our work, it’s our work’s very essence. Learn more from https://youtu.be/gxANBtRJE5g

In the industrial painting industry, two phrases commonly come up – Quality Control (QC) and Quality Assurance (QA). While they may sound similar, they have distinct meanings and functions that are crucial to the success of any coating project. As a professional, AMPP level 3 certified surface inspection company, Toronto Industrial Painting understands these differences intimately, offering complete coating inspection services for all industries. Let’s break down these concepts and their implications for coating inspection.

Quality Control: The Contractor’s Responsibility

Quality Control (QC) is primarily the responsibility of the person or the party executing the work, which in the case of the painting industry, is typically the contractor. Contractors may employ a coating inspector to ensure that their work complies with specified guidelines or, when such guidelines are absent, adheres to accepted industry standards for efficient coating practices.

However, a potential conflict can arise between maintaining Quality Control and meeting project deadlines or financial constraints. Even the best contractors might be tempted to compromise on quality to meet project timelines under client pressure. If a coating inspector is working under a contractor for quality control, this pressure can put them in a challenging position. As the measurements recorded in the QC process might be used in the future to ascertain the quality of work if a failure occurs, it is crucial for these figures to reflect the truth.

Related: What Do MPI-Certified Architectural Coatings Inspectors Do?

Quality Assurance: The Independent Inspector’s Role

Quality Assurance (QA), conversely, is usually undertaken by an independent entity. In industrial coating scenarios, this often falls on a third-party coating inspector. This process assumes that Quality Control has been executed and that the work has been approved for inspection by the contractor.

The QA inspector’s task is to verify that the work aligns with the project’s documentation and specifications. If a contractor doesn’t employ a QC specialist, the QA inspector takes on both roles, leading to increased responsibilities, especially if the work requires multiple rounds of inspections due to substandard quality.

Related: Understanding the inspections process

The Specialized Role of Toronto Industrial Painting

At Toronto Industrial Painting, our AMPP Level 3 certified coating inspectors specialize in performing detailed and unbiased Quality Assurance checks. Recognized by the Association for Materials Protection and Performance (AMPP), we bring a unique, highly qualified perspective to the job. Our three levels of certification – Level 1, Level 2, and Level 3 – underscore our commitment to delivering top-quality inspection services across all industries. We also offer consultation on quality assurance and control measures, making us a one-stop solution for all your industrial painting inspection needs.

In an industry where poor quality or hasty work can lead to expensive repairs and potential operational disruptions, our singular focus is to ensure the longevity and integrity of your assets. At Toronto Industrial Painting, quality isn’t an add-on – it’s woven into the very fabric of our ethos.

Toronto Industrial Painting is a leading player in the coating inspection industry with a remarkable history of professional services across various sectors. Our key competence is our AMPP Senior Certified Coatings Inspectors, recognized for their proficiency in third-party QA/QC, bridges, petroleum, pipe, paint, specifications, failure analysis, project estimation, nuclear facilities, tanks, and lead abatement.

Bridges are among the key infrastructures that benefit from our robust industrial painting services. A major component of this process is the surface preparation, application, and inspection of protective coatings on bridge steel, either in a shop or field setting. This article provides a succinct overview of these processes.

Understanding the Inspection Process

The coating inspection process is integral to bridge coating application. It encompasses several checks to ensure that the surface is suitable for coating and that the coating is applied properly. A thorough bridge coating inspector can help identify any potential issues that could undermine the coating’s longevity and effectiveness. As NACE Coatings Inspectors working in Toronto, Ontario, our team possesses the expertise and the meticulous eye for detail needed for such a critical job.

Related: Professional Coating Inspection Services in Southern Ontario

Surface Preparation

The longevity and effectiveness of a protective coating largely depend on the surface preparation. Surface preparation involves removing all foreign materials such as rust, mill scale, old paint, and other contaminants that could prevent the protective coating from adhering properly. It’s crucial to ensure that the surface is clean, dry, and roughened to enhance the coating’s adhesion and overall performance.

Application of Protective Coatings

Applying protective coatings on bridge steel is a procedure that requires precision, experience, and the use of the right products and equipment. Depending on the bridge’s location, exposure, and specific requirements, we select the most suitable coating to offer long-lasting protection against weathering, rust, and other environmental factors. Our team is skilled in utilizing a variety of application techniques, each designed to achieve optimal results.

Containment

Containment is a crucial aspect of the bridge coatings process. It serves to prevent the release of harmful materials, such as lead-based paint or rust particles, into the environment during surface preparation and coating application. At Toronto Industrial Painting, we take environmental protection seriously. We employ effective containment methods that comply with environmental regulations and best practices.

Field Safety Hazards

In a field setting, safety is paramount. Various hazards can arise, ranging from working at height, dealing with heavy machinery, exposure to harmful substances, to other potential risks. As an industry leader, we adhere to strict safety measures to protect our team and the surrounding environment. Our staff is fully trained and equipped to manage these risks, ensuring a safe and efficient working environment.

Related: What Do MPI-Certified Architectural Coatings Inspectors Do?

Adapting to Changing Weather Conditions

Weather conditions significantly impact the surface preparation and coating application process. Factors such as temperature, humidity, and precipitation can affect the coating’s curing process, adhesion, and durability. Our experienced team is adept at adapting to these changing weather conditions. We monitor and adjust our work practices as needed, ensuring that every job is completed successfully, regardless of the weather.

In conclusion, at Toronto Industrial Painting, we take pride in our team of AMPP Certified bridge coating inspectors who have demonstrated unparalleled expertise in the industry. We strive to provide excellent services that assure the longevity and safety of your infrastructure.

Whether it’s for a bridge, petroleum facility, nuclear tank, or lead abatement, we’re equipped to handle your industrial coating needs. Give us a call at 416.444.5092 and let us provide you with the quality service your project deserves. Learn more from https://youtu.be/6UhtMkowPeg